- Dubai,

UAE

- +971 552730169

info@connectivetrading.com

Chemical Products

- Home

- Products

Showing chemicals & compounds results

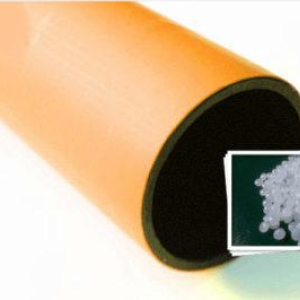

PE-Polyethylene Fillers

Fillers rank among the world's major raw materials and are contained in a variety of goods for daily consumer needs. The top filler materials used are calcium carbonate, kaolin, talc, and carbon black. Filler materials can affect the tensile strength, toughness, heat resistance, color, clarity, etc.

Widely used by most manufacturers of plastics products due to saving on production costs as well as raw materials. The importance of filler masterbatch is in improving the physical properties of plastics and production efficiency. With the advantage of price and stability, plastic filler supports the production of: Blow molding, Blown film & lamination, Extrusion (pipe, sheet), Injection Molding, Nonwoven fabric, Raffia, thermoforming

PP-Polypropylene Fillers

Fillers rank among the world's major raw materials and are contained in a variety of goods for daily consumer needs. The top filler materials used are calcium carbonate, kaolin, talc, and carbon black. Filler materials can affect the tensile strength, toughness, heat resistance, color, clarity, etc.

Widely used by most manufacturers of plastics products due to saving on production costs as well as raw materials. The importance of filler masterbatch is in improving the physical properties of plastics and production efficiency. With the advantage of price and stability, plastic filler supports the production of: Blow molding, Blown film & lamination, Extrusion (pipe, sheet), Injection Molding, Nonwoven fabric, Raffia, thermoforming

B2 PP Fillers

PP is the lightest kind of plastics with a thickness of 0.90 g/cm3. Homo-polymer PP...

Engineering Compounds

Engineering polymer compounds have various applications in the field of food packaging, automotive industries, home appliances, pipes, fittings, (etc...) due to having better Impact properties, flexibility, rigidity, creep, thermal resistance, flame retardancy and many other characteristics than ordinary plastics.

Engineering polymer compounds are materials that are reinforced by other polymers or mineral additives, including glass fibers or mineral powders such as talc and mica powder or a variety of rubbers. These materials have superior technical specifications compared to ordinary plastics.

B3 Engineering Compounds

Engineering polymer compounds are materials that are reinforced by other polymers...

Calcium Carbonate

It is a common substance found in rocks as the minerals calcite and aragonite It has a white/off white color and is one of the abundant materials on Earth

1) Used in the

construction

industry and

less in the

medical industry

as a calcium

supplement.

2) Heavily used

in the polymer

industries

including

plastics,

paints,

adhesives,

household

cleaning among

others

3) Employed in

the plastics

industry for

enhancing

efficiency,

product

thermo-mechanical-chemical

properties,

processing,

cost, color

among others.

Titanium dioxide

Inorganic compound with the chemical formula TiO2. It is a white, water-insoluble solid

2) The most widely used white pigment because of its brightness and very high refractive index.

3) TiO2 is used extensively in plastics as a white pigment and for its UV resistant properties where the powder disperses light – unlike organic UV absorbers – and reduces UV damage, due mostly to the particle's high refractive

Fluoropolymers

It has better high temperature stability than mostly any other plastic. They are not as susceptible to the van der Waals force as hydrocarbons. This contributes to their non-stick and friction reducing properties.

It is heavily used as a polymer processing aid in applications such as Cast films, Blown films, Extrusion flat-die, Sheet extrusion, Thermoforming, Compounding, injection molding. Their uses substantially enhances machine processability and product technical performance

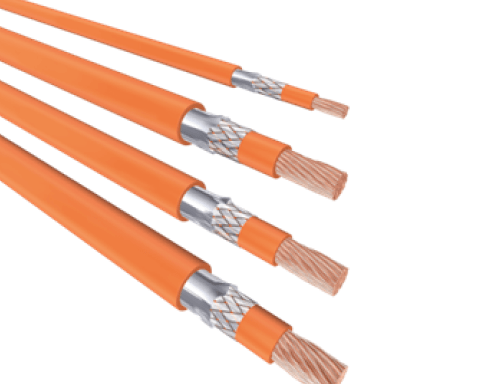

Magnesium hydroxide

An inorganic white compound which occurs in nature as the mineral brucite. Has smoke suppressing and flame retardant properties attributable to the endothermic decomposition it undergoes at 332°C

Common uses of magnesium hydroxide as a flame retardant include cores of aluminum composite panels (ACP), additives to cable insulation materials, insulation plastics, roofing, and various flame retardant coatings

Talc

Is a clay mineral. It occurs as foliated to fibrous masses, and in an exceptionally rare crystal form. Talc is translucent to opaque, The Mohs scale of mineral hardness, based on scratch hardness comparison, defines value 1 as the hardness of talc, the softest mineral.

Talc is used in many industries, including plastics (blown/cast film extrusion, injection molding), rubber, electric cable, pharmaceuticals, cosmetics, food…

Calcium stearate

Is a carboxylate salt of calcium. The salt is a component of some lubricants, surfactants, as well as many foodstuffs. It is a white waxy powder

1) Heavily used in

plastics production

acting as a

processing aid, a

lubricant, and a

release agent.

2) It helps in the

production of

high-quality fillers

(CaCO3, talc, white)

which are heavily

used in extruded

cast/blown films,

blow molding, and

injection molding

applications.

Antioxidants

Are compounds that inhibit oxidation which is a chemical reaction that can produce free radicals and chain reactions that damages the polymers That damage of polymer molecules leads to bad technical performance and machine processing.

Antioxidant polymer stabilizers are widely used in thermoplastics, rubber, elastomers, and adhesives to produce high-quality products in applications such injection molding and blown/cast film extrusions among others.

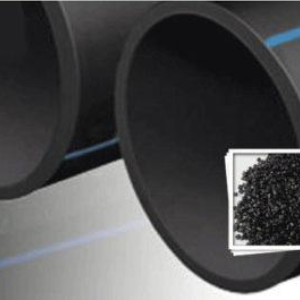

Carbon Black

Is a material produced by the incomplete combustion of coal and coal tar, vegetable matter, or petroleum products, including fuel oil. It has a black color and it is the most used black materials in the world

1) Widely used as a

colorant and

reinforcing filler

in plastics and

rubber products

2) Heavily used as a

wear protection

additive in

plastics.